|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

How to Make a Set Up Box |

Two Radically Different Approaches to Packaging

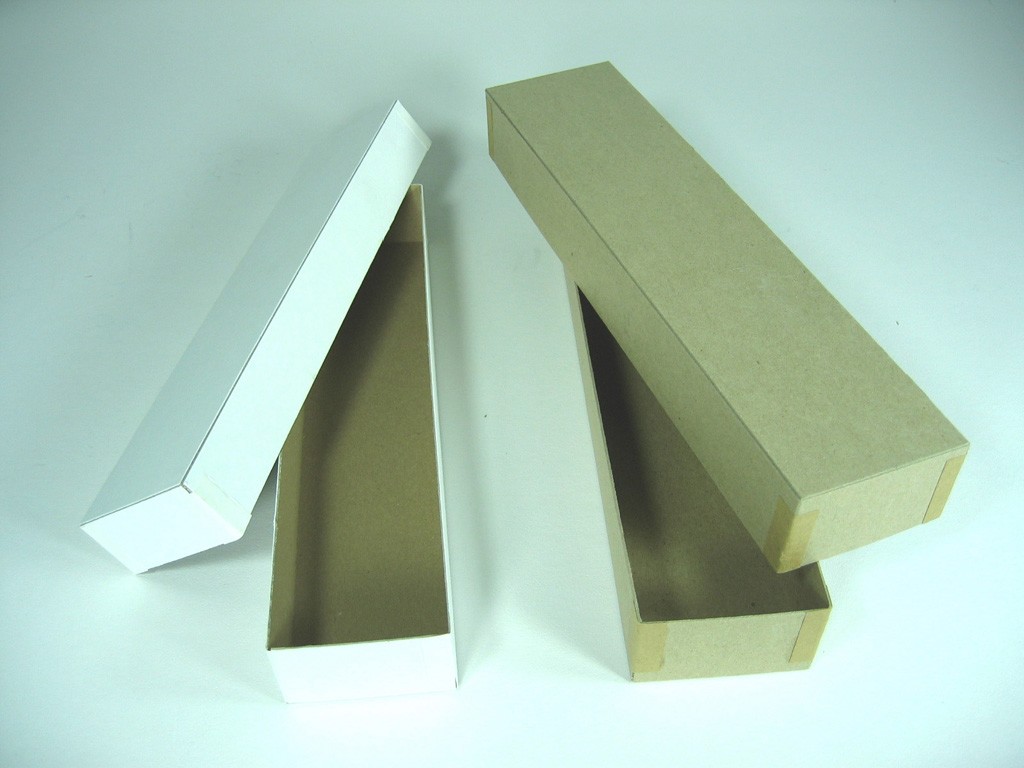

Before we investigate the actual manufacturing process, let's consider the differences

between a folding carton and a set-up box. At first glance, it may be difficult to tell them apart.

The base and lid on the left look pretty much the same as the boxes on the right.

|

|

|

| Image courtesy of eNasco.com | Image courtesy of Jordan Box Company |

Take a closer look, however, and you'l see that the panels on the box on the left have

been folded over to make up the box. The lid on the right is made from a single piece of

chipboard, cut-scored to fold, with the sides held together by tape.

The sample on the left is a folding carton; the one on the right is a set-up box.

|

|

|

| Image 1 | Image 2 |

A set-up box can be distinguished from a folding carton in three major ways:

A wide variety of wraps may be applied to a set-up box,

including padding, leather, fabric and flocked (a decorative

finish accomplished by applying fine fiber particles to the |

|

|

| Image 3 courtesy of tangodesign.com.au |

Each type of paperboard packaging has its uses. Here is a comparison of some of the advantages of each method of manufacture.

Folding Cartons vs. Set-Up Boxes

| Folding Carton | Set-Up Box | |

| Shipped folded flat for lower transportation costs | X | |

| Usually does not require expensive steel-rule die | X | |

| Faster production speeds & lower unit costs | X | |

| Manufactured with relatively low carbon footprint | X | X |

| High consumer appeal in select "luxury" markets | X | |

| More durable for extended reusability | X | |

| High quality printing, embossing, foil-stamping | X | X |

| Made from sustainable, recyclable materials | X | X |

| Generally does not require separate base & lid | X | |

| Requires no setup for product filling | X | |

| Complex, sophisticated structural designs | X | X |

Set-up boxes have been in use since the late 1800's. Today, there are many variations of possible styles, some of which may be

seen on the following pages. For our purposes, we will describe the manufacture of the most basic style,

the wrapped set-up base and lid.

Non-bending chipboard, the material most often used for rigid boxes, may range from .040 (40 thousandths of an inch)

to .080 or more. Compare this to folding cartons, whose stock may vary from .010 to .036. Note that there are many types of

substrate used by folding cartons depending upon the end use of the packaging, but most set-up boxes use chipboard.

This is because in set-up box manufacturing, the finishing is done to the wrap, not the substrate.

The exception is when a material called white vat-lined chip is used. In this case, the chipboard is lined on

either one or both sides with a white coating made from newsprint, giving the box a more finished appearance.

This stock works especially well if the interior of the box is to remain unfinished, or unlined.

By contrast, Image 5 shows some samples of lined boxes.

|

|

|

|

Image 4: a pallet of double white vat-lined chip courtesy of Burt Rigid Box |

Image 5 courtesy of Burt Rigid Box |

The goal in set-up box manufacturing is to bring the wrap and the formed chipboard lid or base together, adhering them in perfect alignment before forming the finished tray. Of the six fundamental steps in the production of a set-up box, two make the box, two produce the wrap, and two bring them together to produce the tray: for the tray scoring and staying; for the wrap printing/preparation and applying adhesive; and finally, for the completed tray - spotting and wrapping.

The Tray

Cutting and Scoring

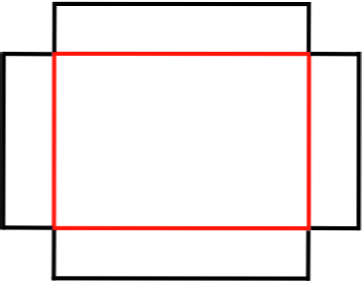

We start with a cut-scored tray, which depending upon the box's dimensions, looks like this:

The simple steel rule die for the tray contains knives (the black lines) for cutting out the overall shape from the chipboard, and cut-scores (the red lines) for allowing the panels to fold. Cut-scores only partially penetrate the chipboard, allowing bending without tearing.

|

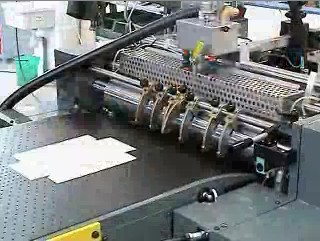

Staying Set-up boxes can be made without stay tape, but for added stability, ¾" wide adhesive backed tape is applied to the four corners of the tray on a machine called a quad stayer. Image 6 shows an example of an older manually fed model. Two of the four rolls of tape are clearly visible; the other two are blocked by the ones in front. The chipboard blanks are fed into the machine, a plunger forms the box, tape is applied and heat-sealed to the tray. You can see how the taped box looks after it leaves the stayer by reviewing Image 2 above. |

Image courtesy of circinusinternational.com |

The Wrap

Printing/Preparation

Not all set-up box wraps require printing, but this option, plus foil stamping, embossing,

debossing and other decorative techniques; almost anything that can be glued to

chipboard and formed into a box are available. Below are just a few examples.

|

|

|

| Image courtesy of Brimar Packaging | Image courtesy of Burt Rigid Box | |

|

|

|

| Image courtesy of NAPCO | Image courtesy of Taylor Box Company | |

|

|

|

| Image courtesy of The Dieline.com | Image courtesy of Hazen Paper Company |

Whatever wrap is used, it must be trimmed before adhesive is applied. The corners are cut away or mitred so that when the box is formed, the wrap makes a perfect transition from two-dimensional blank to three-dimensional box. Image 7 below shows a mitred wrap blank before it is applied to the lid or base.

Gluing

There are two methods of adhering the wrap: tight wrap, the most typical technique; and loose wrap.

The tight wrap method applies adhesive to the entire back surface of the wrap. In Image 7,

a corner cut wrap has just left the gluer on its way to the spotting station, where the formed lid

or base will be positioned and placed onto the wrap.

Loose wrap is generally applied only to the lid of a box, and as the name implies, the wrap is only spot-glued

at the edges, leaving the top panel without adhesive. The purpose of this type of gluing is primarily aesthetic:

a box made with a loose wrap appears to be hand-made, and therefore a more expensive package. Back when much

of the production was indeed done by hand, loose wraps were more common. But in today's automated environment,

loose wrap constitutes only a small percentage of total production.

Image 7 courtesy of Emmeci S.p.A.

This brings us to the last two stages of production, where the wrap and tray meet to become a finished piece.

Completing the Lid or Base

Spotting

The term spotting is derived from the days when an operator would position, or spot the lid or base onto the wrap,

"eyeballing" the correct position. While this operation is still done manually in some operations, with the advent

of electronic eyes and more sophisticated positioning equipment, the process is becoming more and more automated.

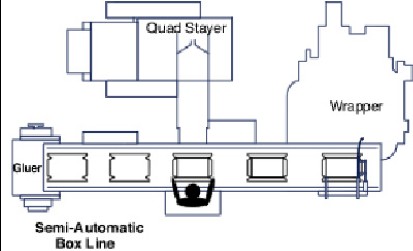

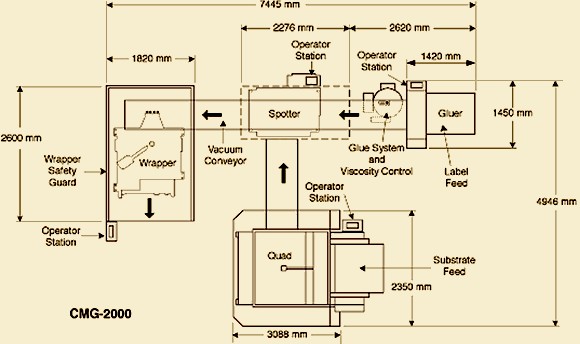

Figure 1 below shows where an operator would be positioned in a semi-automatic boxmaking line.

Figure 1 courtesy of Paul T. Freund Corporation

The wraps, adhesive-side up, move along a conveyor from the left. The lid or base, having been formed in the quad stayer, moves toward the operator from the top of the diagram. The operator then carefully (and quickly) places the tray on the glued surface of the wrap. From there, the box moves to the right toward the wrapping station. In an automated line, the spotting station appears as it does in Image 8. If you look closely at the top center of the shot you can see a machine-positioned base descending toward the wrap below. At the bottom left of the picture is a base that has just left the station, now ready for wrapping.

|

|

|

|

| Image 8 courtesy of Emmeci S.p.A. |

Wrapping

Pressure is applied to the top of the unwrapped tray to help the glue adhere, then the box moves into the wrapper.

This operation can be seen in Image 9. Arms grab the tray and pull it at a right angle into the wrapper.

The red plunger pushes the lid or base down where the adhesive laden wrap is rolled up and over the tray,

gluing it to the sides and onto the inside lip of the box, giving it what is called a turned edge.

Image 9 courtesy of Emmeci S.p.A.

To get a bird's eye view of the entire process, see Figure 2. Don't be misled by the many "operator stations" noted in the layout. These are terminals where a single operator, when everything is running smoothly, can oversee the automated process.

Figure 2 courtesy of Crathern Machinery

If a picture is worth a thousand words, then a video must be worth a million. To see how an automated set-up box line works in action, courtesy of Emmeci S.p.A., please enter the link below into your browser, then click "VIDEO."

http://www.emmecifucecchio.com/catalogo_scheda.php?idprodotto=5

More Styles and Shapes

Rectangular lids and bases are by no means the only choices available set-up boxes.

As these pictures from Burt Rigid Box illustrate, ovals, rounds, drums, even sifter rings are available.

|

|

And finally, come each February, perhaps the most memorable shape in set-up boxes may be seen in profusion.

Image courtesy Godiva Chocolates

Paperboard Packaging Council

1350 Main Street, Suite 1508

Springfield, MA 01103-1628

Phone: 413.686.9191

Fax: 413.747.7777

E-mail: info@ppcnet.org